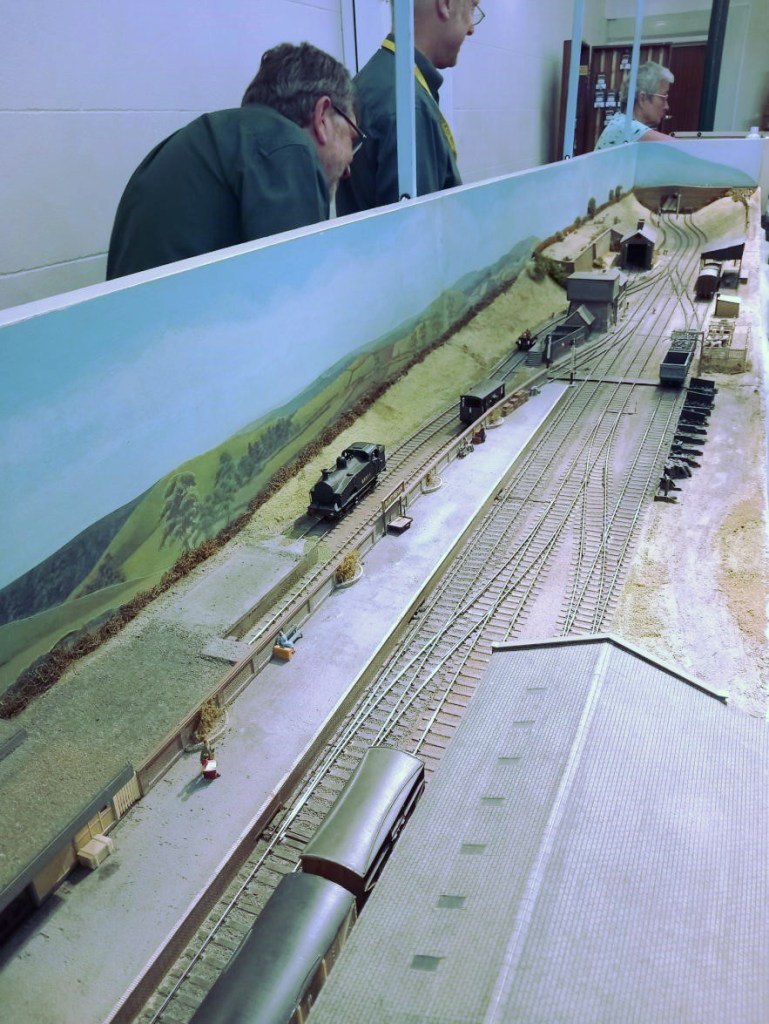

The Summit (pictured below at its first showing in Telford in 2015) will be heading to the Model Rail Scotland Show in Glasgow in February and our focus is now on getting this huge 7mm Scale 0 Gauge layout fully up to speed and ready for a three day show and a lot of miles in a 3.5 Tonne lorry – good job they come with tail lifts nowadays!

The Summit has also been invited to another three day show, the Bristol Model Railway Exhibition at Thornbury at the beginning of May, so some busy days ahead for the team!

Allan has added an ex-GWR small prairie, the preserved 4555 to his fleet of 7mm locomotives. Now fully converted to 7mm, he is advertising the sale of his lovely 4mm 00 Gauge layout “Kingsferry” in the next issue of ‘Railway Modeller’ and is planning an O gauge model of Cole on the S&D to replace it.

Dom has not been idle with his 4mm scale 00 gauge layout Combe Town, and recent progress can be seen above. He’s spent plenty of time building over 2′ of fencing along the front side of the railway (only another 4′ to go!), and has put the initial ground cover down in the field and on the yard surface. For good measure he built one of the Smith’s loading gauges.

Your editor will spare his blushes as to why, but Dave H’s beautiful scratchbuilt 7mm scale Deeley 990 Class 4-4-0 requires complete replacement. It’s another 4-4-0, but this time it’s a green one – City of Gloucester as built in 1903. It’s based on a Finney kit but heavily modified so it can be dismantled for painting and maintenance, which is tricky for a double framed engine.

He’s also modified the tender so it will weigh on the rear of the loco. The tender underframe is mostly complete, and he’s made a start on the loco underparts. Dave reports that it’s a good kit and all is going well.

Continuing the ex-GWR theme, Pete C is finding the conversion of a 4mm scale Rapido model of a 15XX Hawksworth pannier tank to EM Gauge something of a challenge. This conversion is complicated by non-availability of wheels (they’re standard size GW wheels, but with a unique crank throw). The axle size is 2mm and the pickups are an unusual style of plunger pickup which has turned out to be unworkable with a widened back to back. The factory assembly wasn’t the best either, this engine having the same i.e. incorrect not handed coupling rods. The clearances proved just sufficient behind the crosshead by deepening the crankpin hole, which could then be screwed in another 0.5mm.

The wheels are pressed onto splined axles with top hat bushes which proved insufficiently long to reuse. Delrin rod was obtained and using the Unimat lathe new bushes were made by trial and error – more than enough were made to get ones that fitted accurately. Roughening the new axle ends with a file appears to have been sufficient to stop the wheel slipping on the axle. The original axle face was moulded on the wheel but was cut away allowing the bush to extend the whole way through the wheel and then trimmed.

New pickups were fitted to the keeper plate using copperclad glued and connected together by 0.35 brass wire on the top surface and reconnected to the circuit board plug through a new hole drilled in the chassis block. New return cranks have been filed from nickel silver sheet and riveted to the motion using Markits rivets. Only the front axle uses the Rapido screwed in crankpins, Romford crankpins have been used as the wheel threads were compatible. New spacers were drilled and turned to size, the return crank will be the final item reassembled after basic testing as they’re soldered on the crankpin.

As the conversion proceeded more and more parts were removed, it’s a good job an exploded drawing is on the web! The buffers are pretty poor and fitted badly, they’ll be replaced with brass ones. Otherwise the detail is excellent, including in the cab where it can’t be seen!

Derek is a fairly new member to YMRG. Recently he’s had some time on his hands, so he made a start building a kit he bought at Guildex in September. The kit is for an ash plant, and above are two photos of the work so far. He will replace the wooden railings (not shown) with wire ones, paint the model and then fix the roof on. This will eventually be used on a model of an LMS MPD.

Simon K has acquired this 3D printed shed, coal store and water tower for a little quarry based layout that his wife and some ‘friends’ have decided will be a good project to keep him busy. Most of it will be built by a chap near Ludlow, but he will be doing buildings, people, stock and detailing as it suits him.

And this is Simon K driving Alice on the Bala Lake Railway.

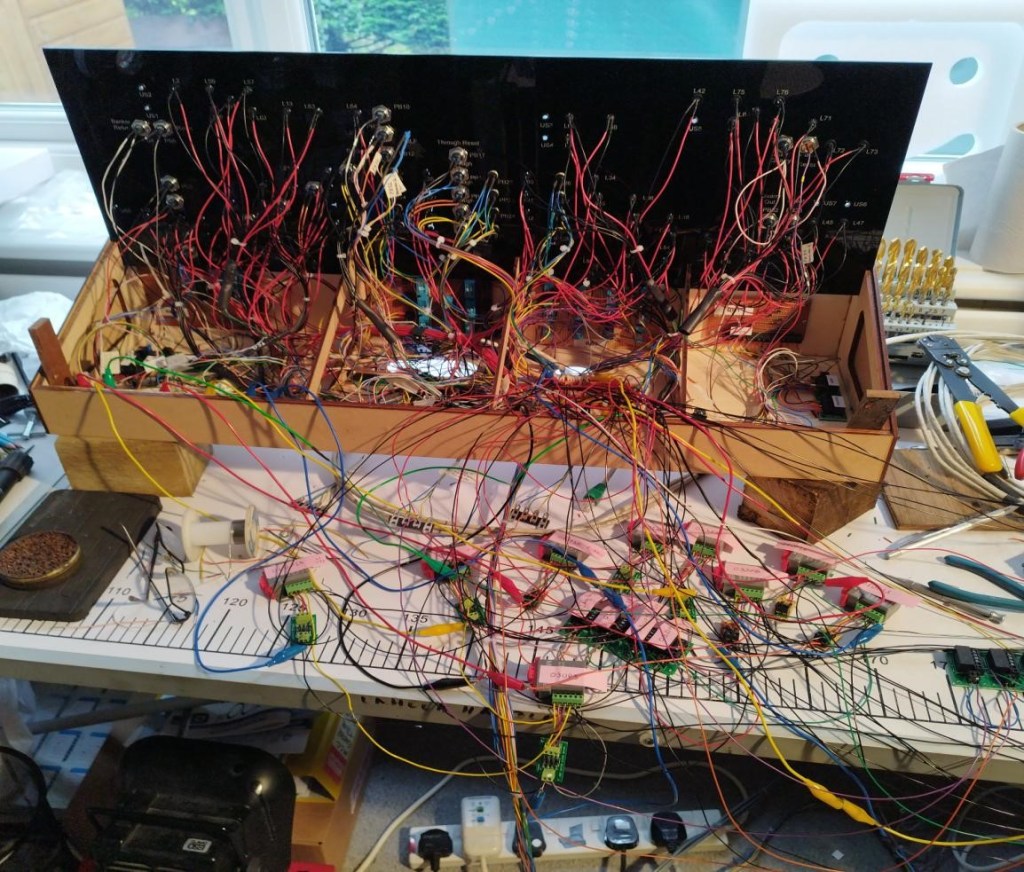

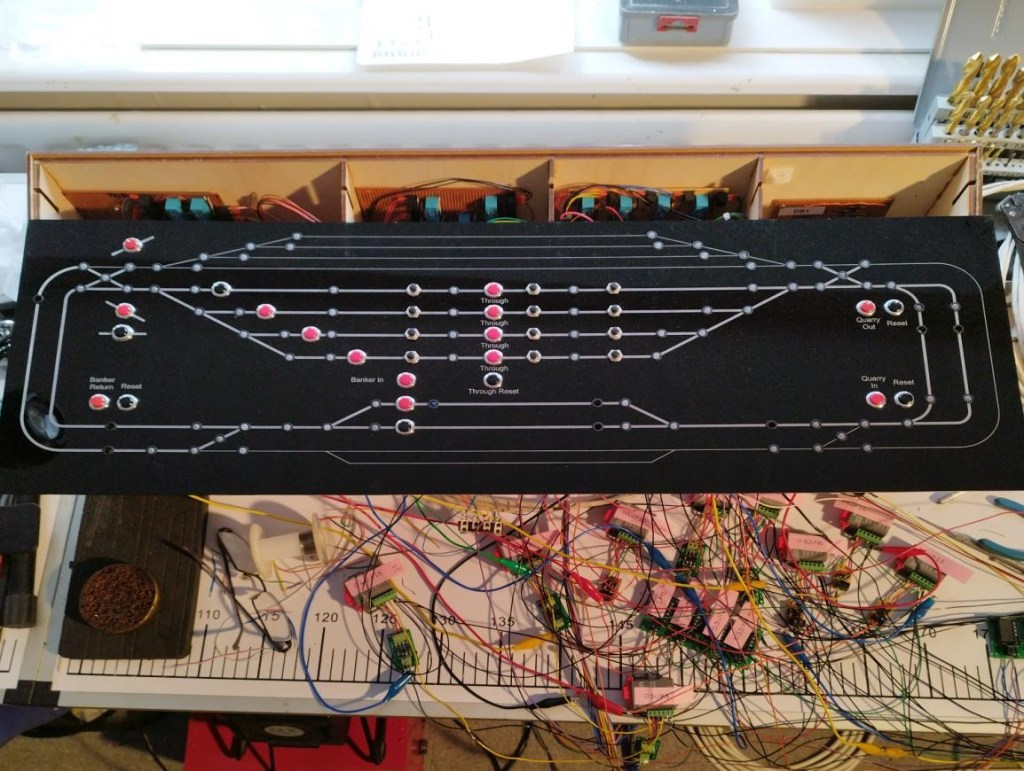

Former Chairman Dave S installing the control panel on our 2mm scale N Gauge club layout The Bank with Hon. Secretary and Layout Co-ordinator Dean looking pleased, and Hon. Chairman Ed providing vital moral support.

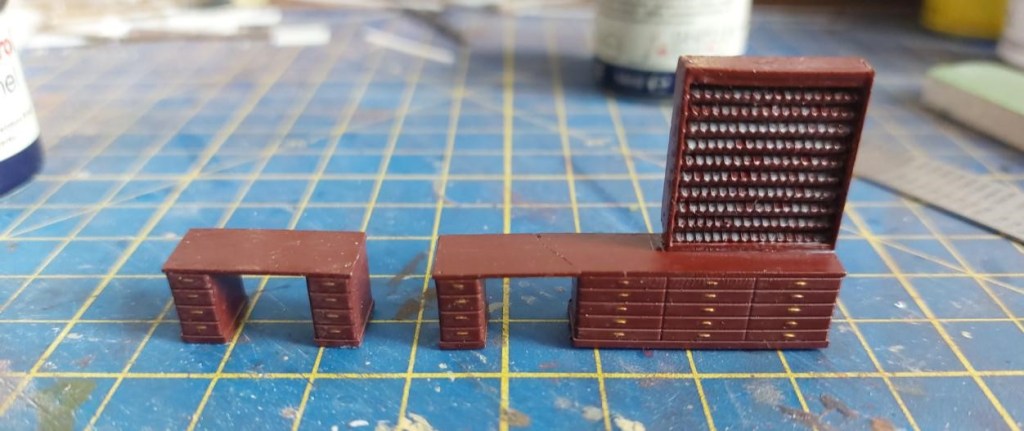

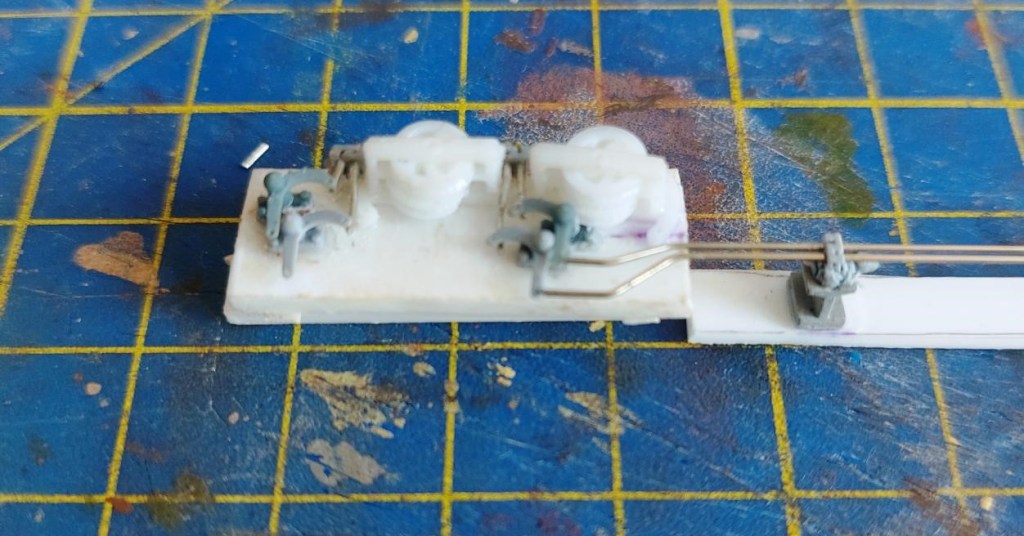

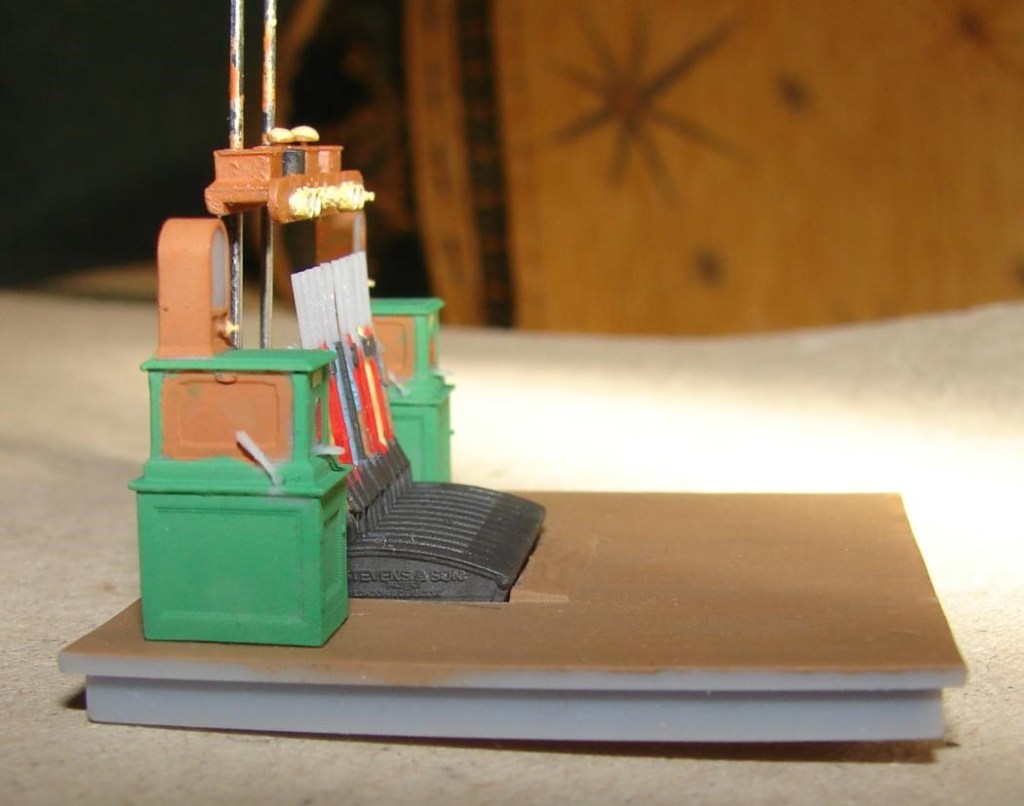

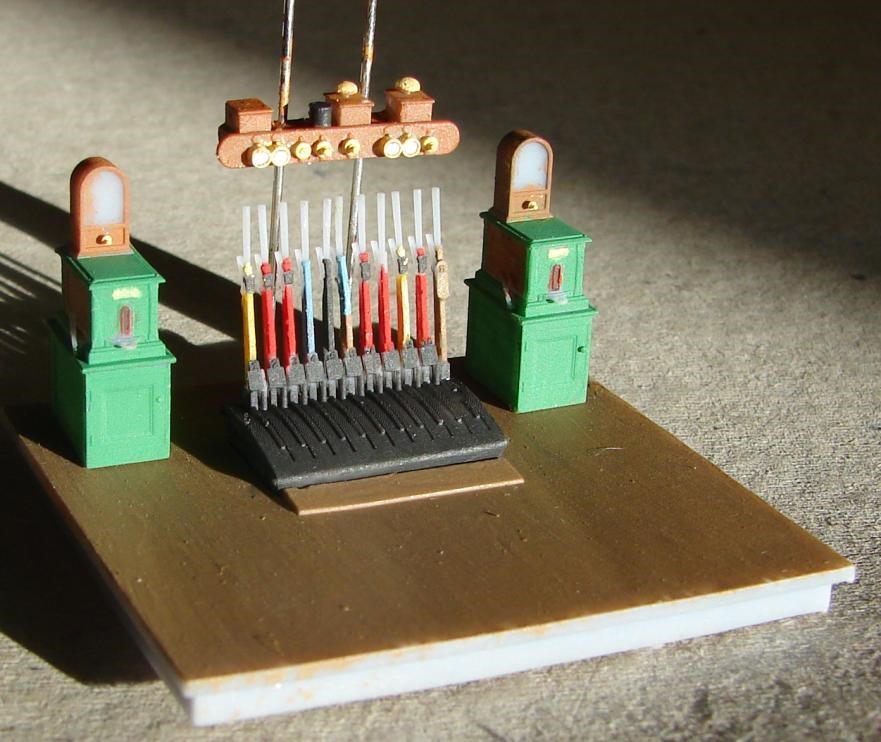

A couple of pictures from Steve of his 4mm scale 3D printed lever frame, instrument shelf, and Tyer’s No.6 tablet machines as once found at Verwood, cruelly enlarged to show how rubbish his current 000 brush and eyesight are. Any brass has been painted light yellow which seems to work well. It was anticipated that ‘STEVENS & SON’ would be legible after painting, but one can just about make out ‘PATENT’ and ‘LONDON & GLASGOW’ underneath, though the letters are much fatter than they should be due to ‘additive kerf’ – something (that regular readers of the blog will know) makes holes smaller and rods larger in 3D printing.

The levers are incredibly delicate and a comb like jig had to be devised to hold the levers in place whilst the supports were removed; even then, Lever 6 pinged off where it was nice and thick and has had to be glued back on so is wonkier than the others. There is scope for further straightening with the warmth of a hair drier. This lever frame would even better printed in 7mm scale where the levers wouldn’t need to be quite so plump. the number of levers can be varied and alternative lettering is possible for other makers of Stevens & Sons style frames.

One of the plunger buttons is missing from the shelf – it probably came off with a support, and no attempt was made to portray the coiled spring for the gong at the left end – a coil of fine wire being the only option. If it had been realised that the handles on the release lever had come out on the tablet machines he’d have picked them out in black, and I would have dotted the labels above the repeaters if I’d been able to see them. He’s left the steel bits of everything unpainted whilst he contemplates what colour steel should be. The steel poles supporting the shelf at 0.62mm are clearly too thick and should be painted green.

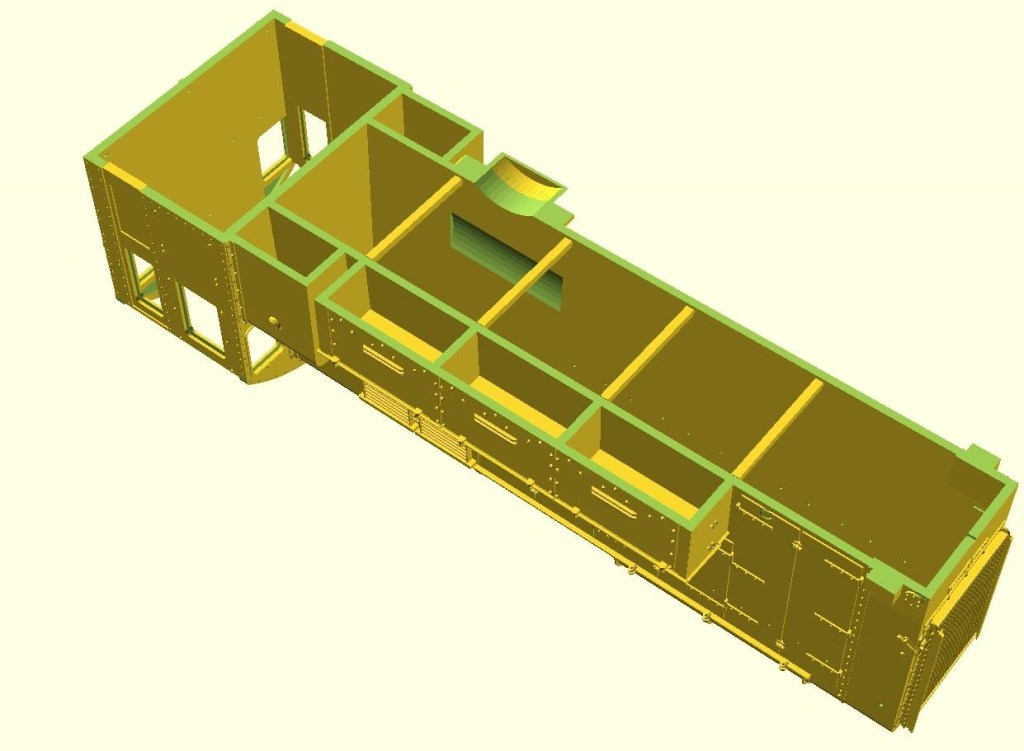

Next up is the painted parts of the Verwood signal box ready for assembly. There are some mistakes. I failed to order the cupboard with desk, pen and register, and need to pick out the lower string course in dark grey, as well as all but one set of brick quoins.

This being Verwood there’s no weatherboarding to the wall under the canopy and no drainpipe on the basis that it drained onto the attached canopy. Jurassic Models cut the sash windows for me and they really look the part and fit well. The sashes had to be redrawn to fit the 3D print and then again to allow for the heavier kerf of the laser used. Due to additive kerf the ‘VERWOOD’ lettering on the 3D printed sign is a little too heavy so I’ve redrawn the lettering 0.05mm less all-round and will re-order.

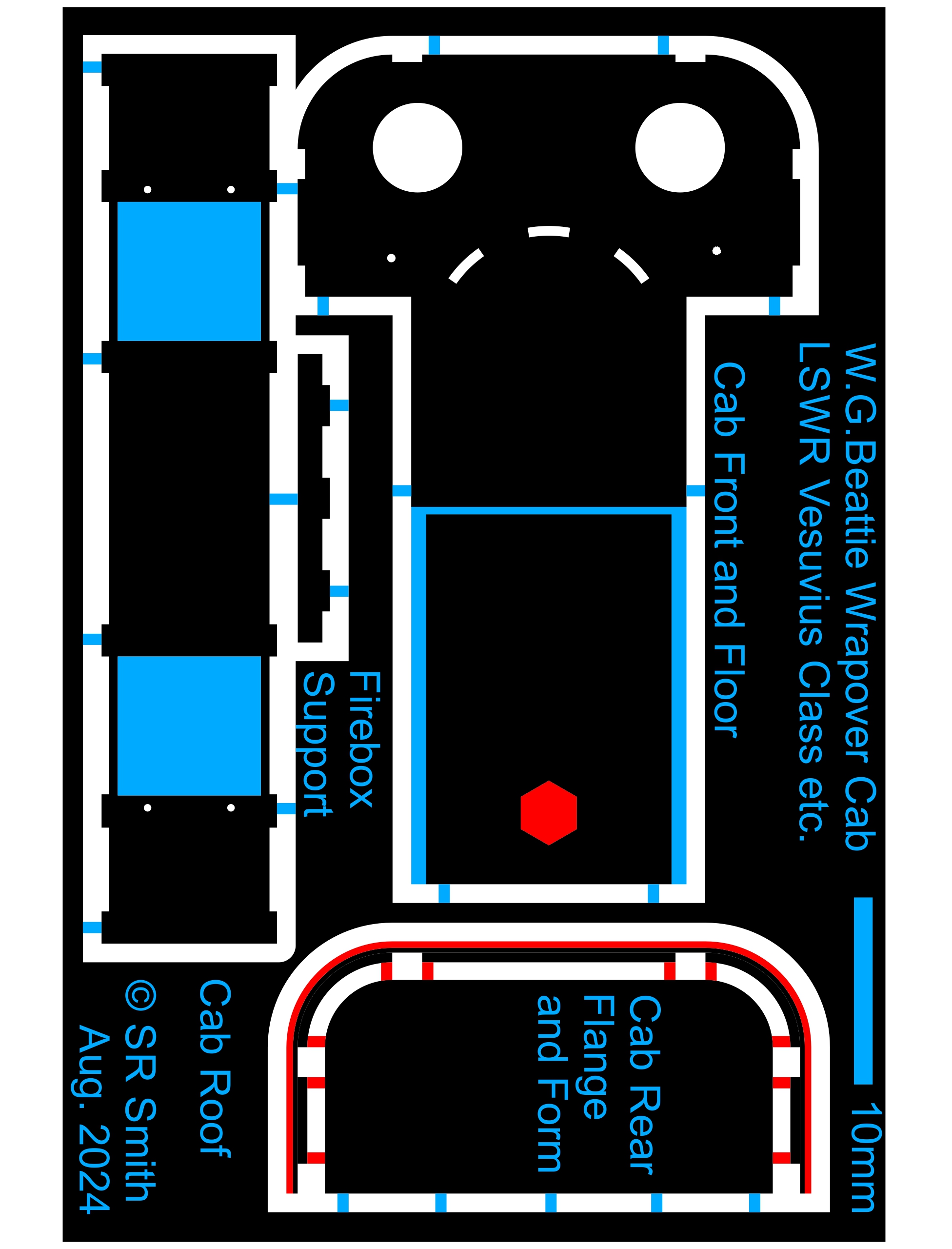

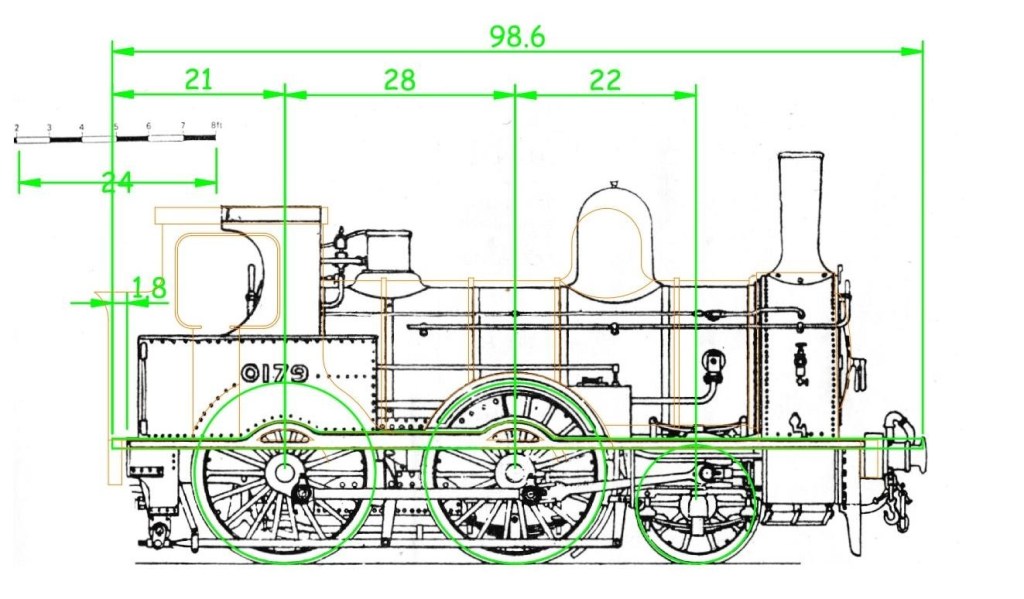

Now for something completely different – cue Monty Python! When the Beattie Well Tanks were being retired from suburban service in the 1880s, thirty were converted to tender engines using Beattie 1950g tenders – those that have been paying attention to these blogs will have know where this is going! So above is the resulting engine with Adams style cab, overlain with a tracing of the Eastleigh Weight Diagram for a Beattie Well Tank in orange. The tender engines were shorter at the front (not having been rebuilt with frame extensions and steel buffer beam), and have pierced splashers, shielded safety valves, different dome and chimney, but otherwise compare well. The green lines are the Kernow running plate and splashers. The intention is that an etch will be designed to replace the cab unit on the Kernow Beattie Well Tank, and to further this, the necessary parts have been drawn up and will be test built in tinplate by a fellow enthusiast for railway engines of the 1880s.

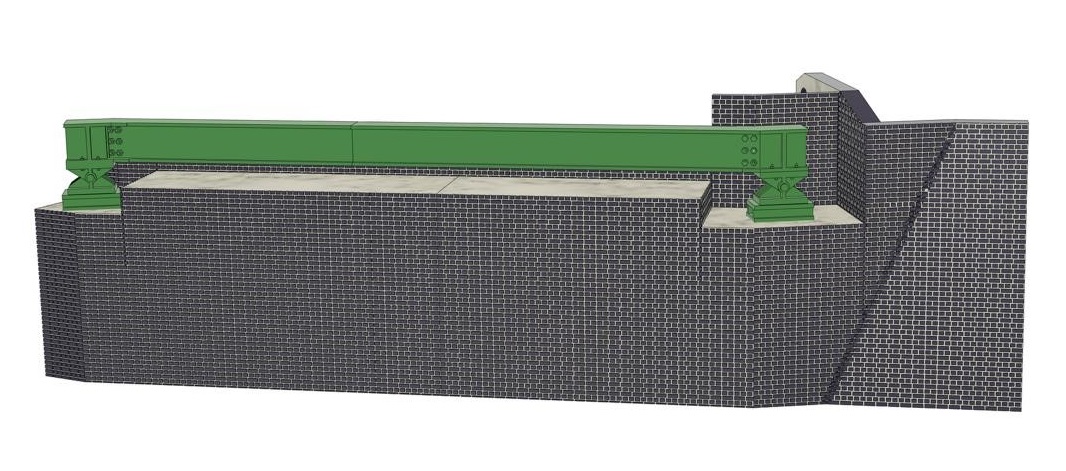

Lastly from Steve the three stone pier caps for Pecking Mill Viaduct (see above). A styrene armature forms the arrises and Milliput was used for the lumpy bits. The many brick pier caps needed will be 3D Printed, and the long runs of brick capping for the parapet will be laser cut and etched.

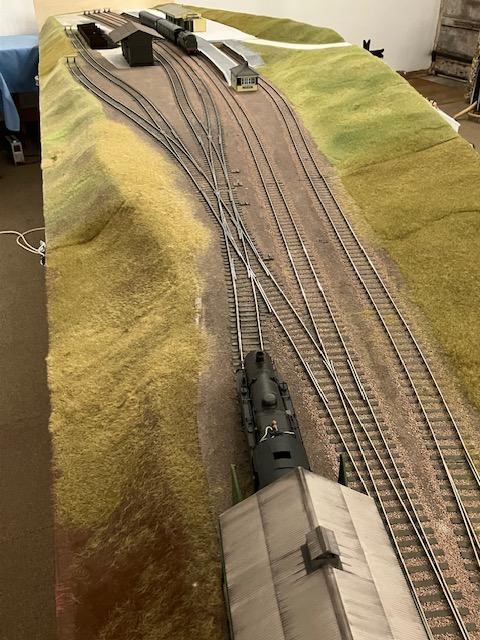

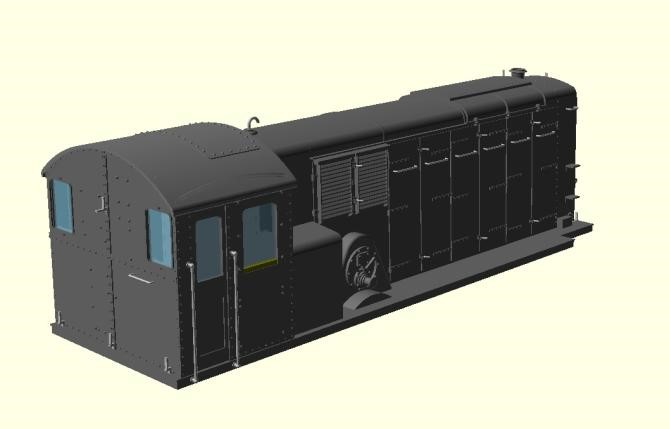

Jim’s LGP (Last Great Project) tentatively titled Bungham Road, will be a 2mm finescale rendition of Littleton Exchange Sidings at Penkridge in Staffordshire, set during the mid 1990s. This is a photo of the prototype, taken by David Rostance from Wolverhampton in 1985. The new layout will be housed in the space vacated by Halsdon Road after its move north.

A picture of the superb second hand fiddle yard boards that Jim has sourced for this project, when they were briefly erected in CS2 back in 2019. Rumour has it that Jim already has more than enough stock to fill all those sidings!